Model No.:

ME48-50 / 50T

Product features:

It is fireproof, durable and environmental friendly with long fibers and without residue balls, not easy to generate dust, helpful for keeping the construction environment clean and thus good for the health of the construction personnel. It has good sound absorption effect and shows no sinking.

Fireproof performance:

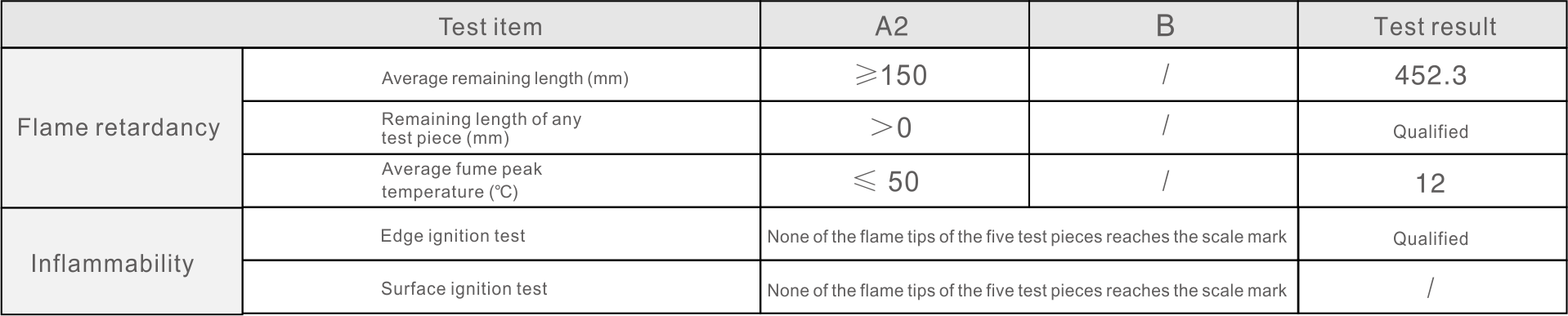

The fireproof inspection results meet the requirements of A2 in GB 8624-2006 and can be directly used for indoor fire prevention.

Application:

Acoustic absorption filling.

Consumption:

Refer to acoustic design

Colors:

White

Density:

48kg/m³

Common size:

1200mm (L) x 600mm (W) x 50mm (T)

Sound Absorption Description:

The red environmental friendly centrifugal glass sound absorption cotton is made by fibration of the melted glass and adding of environmental friendly bonding agents, mainly thermosetting resin. It is felty and elastic, composed of glass fibers with a diameter of just a few microns. As the internal fluffy fibers cross each other, there are abundant small holes, and thus it is a typical perforated sound absorption material with good sound absorption properties

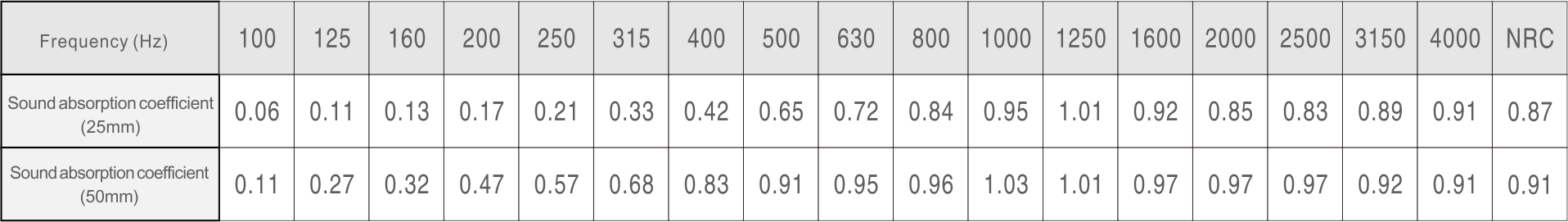

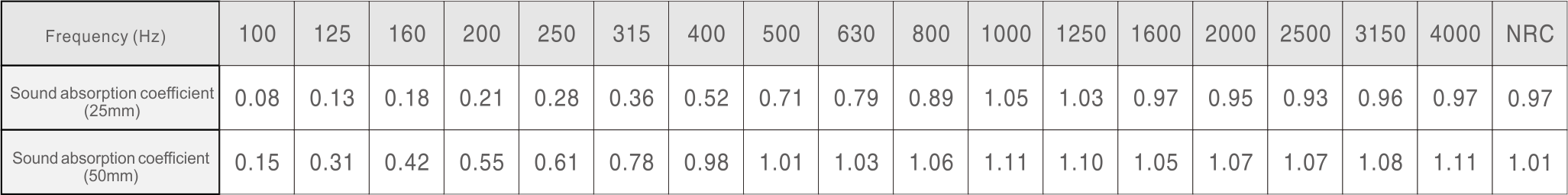

Sound absorption coefficient:

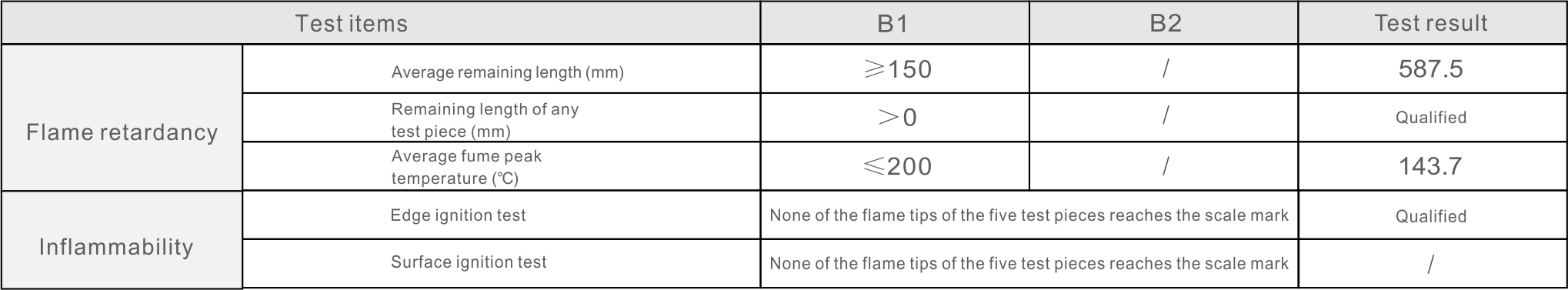

Fire retardant test result:

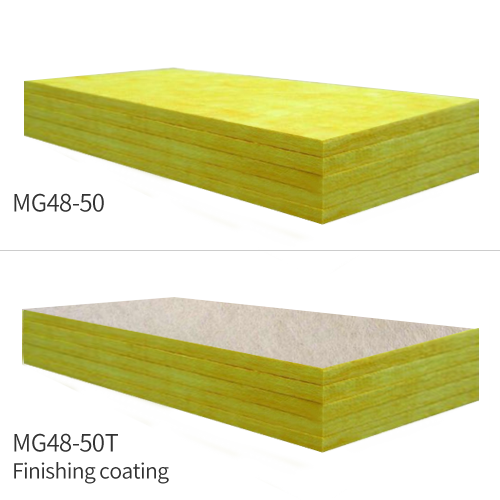

Model No.:

MG48-50 / 50T

Product features:

As it has the advantages of fireproof and anti-corrosion performance, no toxicity, small volume weight, low heat conductivity, strong chemical stability, and good hydrophobicity etc, it is considered the best heat preservation, heat insulation, sound absorption and noise reduction material with significant effect, and can be widely used.

Fireproof protection:

The fireproof inspection results meet the requirement of A2 in GB8624-2006 and can be directly used for indoor fire prevention.

Application:

Acoustic absorption filling.

Consumption:

Refer to acoustic design

Colors:

Yellow

Density:

48kg/m³

Common size:

1200mm (L) x 600mm (W) x 50mm (T)

Sound Absorption Description:

With natural ores as the main raw materials, e.g. quartz sand, limestone and dolomite, along with some chemical substances like sodium carbonate and borax, the centrifugal glass wool is smelted into glass. In the melted state, it is blown by external forces to be flocculent fine fibers, which cross and intertwine each other with many small gaps in between.

As the fluffy fibers cross each other, there are abundant small holes, and thus it is a typical perforated sound absorption material with good sound absorption properties. The centrifugal glass wool can be made into wall sheets, ceiling sheets and spatial sound absorbers, etc to largely absorb the sound energy in he rooms to reduce the reverberation time and the indoor noise. When there is a layer of air behind the glass wool sheet, the sound absorption effect is similar to that of the glass wool sheet of the same thickness without the air layer. In particular, the sound absorption performance for the medium and low frequency sound signals will be much better than that of hard bottom surfaces with attached materials.

The sound absorption coefficient will increase along with the increase of the thickness of the air layer. Through the superposition of glass wool of different volume weight values to gradually increase the total volume weight, even better sound absorption effect can be achieved.

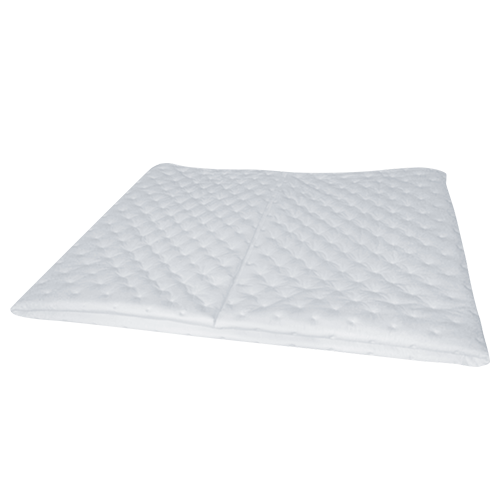

Sound absorption coefficient:

Fire retardant test result:

Project reference:

Name:

Byer Acoustic fiber wool

Model No.:

MP24-20

Product features:

As it does not contain any resin bonding agent and has good environmental protection performance, it is mainly used for households and some building acoustic places with high environmental protection requirements to replace the traditional centrifugal glass wool.

Environmental protection:

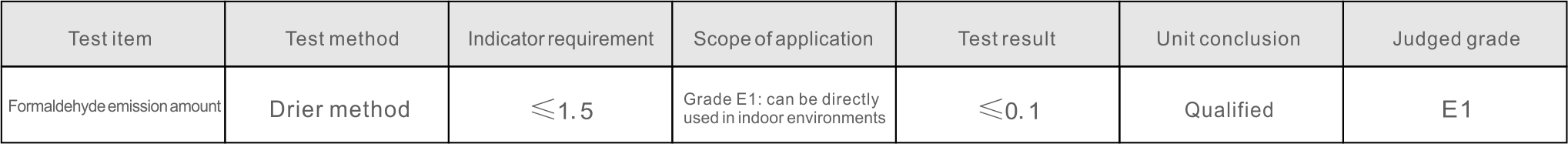

The standard requirement for formaldehyde emission is 1.5mg/L, while the test result is <0.1mg/L, meeting requirement of El in the national standard GB18580-2001, and thus can be directly used for indoor decoration.

Application:

Acoustic absorption filling.

Consumption:

Refer to acoustic design

Colors:

White

Density:

24kg/m³

Common size:

1000mm (L) x 500mm (W) x 20mm (T)

Sound Absorption Description:

The polyester fiber sound absorption board is based on the theory of perforated material sound absorption. There are a large number of small interconnected holes inside the polyester fiber sound absorption board materials, and the sound wave can go deep inside the material through these holes and turns the sound energy to be heat energy by means of friction with the materials. It is a type of perforated sound absorption materials.

Along with the increase of frequency, the sound absorption coefficient gradually increases, which means that the absorption of low frequency sound signals is not as good as that of high frequency sound signals.

The preconditions for sound absorption by the perforated material are as follows: there are a lot of holes in the material, the holes are interconnected, and the holes are deep into the material.

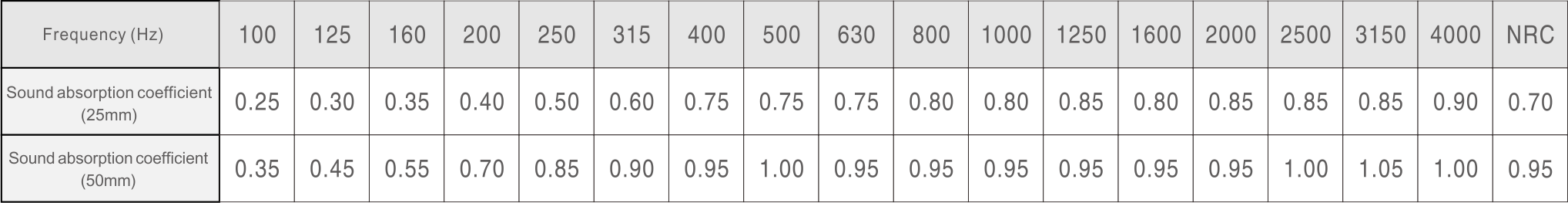

Sound absorption coefficient:

Fire retardant test result:

Environmental indicators: